The AEORC S1 Dr Servo is a tiny box using the same packaging as the clever

kV meter. It consists of a servo driver and an input for an

accelerometer that you attach to the servo’s output disk/arm. That input

measures the pulse position so is also used to test receiver servo outputs.

It also requires an external 8-12V DC supply. They suggest a 2S LiPo, but

after using it I would recommend a 3S. The lower voltage just does not seem

to have quite enough headroom to supply the 5V to drive the servo at higher

currents. Most folks will probably be using the BEC from their ESC to drive

the servos in any case – see the three way cable description later.

The inside of the accelerometer is just a sealed unit

with a part number that I could not raise on the internet with an external

diode and resistor. I suspect it is the same unit used in single axis piezo

helicopter gyros. AEORC call the device a ”gyro” and I’ll do the same for

simplicity. The only control is one of those 4-way joysticks with a centre

push that you find on every compact digital camera. Long push to move

between the 4 screens; up/down/sideways to select a value if appropriate;

short push to turn the backlight on and off or start a test. In my view it

would have been more logical to make the short push for menu change and long

push for backlight/start. The backlight keeps going on and off when you

don’t want it to and on the other hand you have to dwell on a screen to

change to the next one. This results in an unwanted test starting sometimes.

No big deal, and doesn’t detract from the functionality - just an

irritation.

In use, you just plug in the external battery, connect

the servo and gyro and stick the gyro to the servo output disk or arm with

foam tape. Alternatively you can use the gyro input to test transmitter

stick range and centring. There are 4 functions on the tester:

1. Display of

receiver output signal pulse width to the servo channels in thousandths of

mS with a default neutral of 1.500mS (handy to very conveniently check how

consistent the range and neutral your transmitter channels are). A

servo-plug to servo-plug cable is supplied for this and you connect the gyro

channel into each receiver output in turn. The supplied connectors are

Futaba style and the ridges have to be cut off to allow the plugs to line up

along the edge of the S1. Minor, but irritating. This menu must also be used

to set the signal pulse width to give a 60 degree rotation (since the pulse

length to do that may vary from servo to servo).

2. A cycle

test that logs the number of repeating input cycles together with the number

of output cycles recorded by the gyro (good for testing suspect servos). It

reads up to 9999999999 cycles which for a 0.1sec servo would be a total test

time of about 31 years if I have done the math correctly!

3. Measurement

of servo travel linearity, which is really no more than setting up 2 or 3

servos side by side and comparing them as they are driven at the same time.

4. Measurement

of servo speed, which is the uniquely useful and important function of this

gadget.

To measure servo speed, you first need to tell the S1

what pulse width gives 60 degrees rotation. It’s remarkably simple to

position the servo over the protractor they have printed in the manual and

use the joystick to move the servo from the neutral position. When the holes

in the horn line up at 60 degrees, you just read off the pulse width,

subtract the neutral value and adjust it on the measurement screen with the

joystick. It turned out to be much easier and more consistent than I

expected. My guess is it is accurate to a couple of degrees if you are

careful to align your eye with the shaft of the servo on the baseline.

Obsessive can set up a more accurate rig to measure rotation precisely. Then

you just push the button, the servos cycles a couple of times and the time

to move 60 degrees is displayed in 1/100th’s of mS (more on accuracy later).

You can do 10 readings in as many seconds. If the servo doesn’t respond, a

long push upwards on the joystick reverses the signal – neat.

This is the simple way, and uses an internal regulator in

the S1 to provide 5V at a max of 1 Amp to the servo. If you want to measure

at the “standard” 4.8V then use any of the servo connectors on the supplied

three-way splitter lead which then plugs into the S1. See attached picture TestSetup.jpg.

The lead contains a 220µF capacitor to provide some reserve for peak current

draw and a forward connected series Schottky diode in the main lead which

drops the 5V to almost exactly 4.8V and protects the S1 from external

voltages from the branch leads at the same time. Very simple and clever. If

you want to measure at a different voltage, say 6V or use your ESC’s BEC,

then just plug an external supply into one of the three servo connectors.

Results for AEORC S1 Dr Servo

Initially, no servo worked for me without an external

battery supply. Changing the 2S 1000mAh battery supply to a 9V 2.5A power

supply made no difference. I measured 0.46V at the servo supply connector.

AEORC were helpful and responsive but in the end I discovered the Schottky

diode in the harness was assembled in reverse (it’s very hard to spot the

band on the diode). Once fixed, everything worked as expected. Be worth

checking if you have the same problem.

The sensor weighs 9.5g so can be used on quite small

servos. There is no simple way to calculate what the inertial load of the

sensor is on the servo of course so it isn’t quite “unloaded”. Here are a

few sample results averaged over 6 cycles.

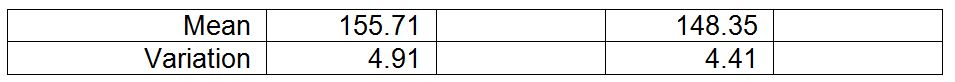

Using a stabilized Lab 2.5A supply:

See Table 1

Using a 40A ESC with 4S 5000mAh LiPo: BEC voltage

measured at 5.16V for same servos as above.

Table1

See Table 2

Using without any external supply gives approx 4.85V at

the servo.

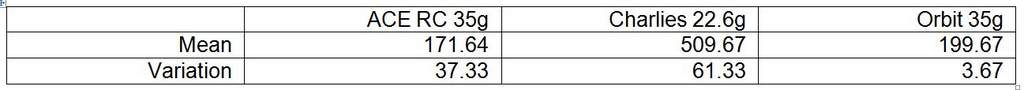

Results without external supply for 3x Bluebird

BMS-375DMG – 11.4g.

Claimed speed at 4.8V = 130mS. Three identical

out-of-the-box, unused servos.

Table2

See Table 3

For fun: Some old servos of late 70’s vintage

Table3

See Table 4

The Orbits were the ultimate small servo at the time,

have served me well, and cost a fortune. They still hold up not too badly 30

years later! The Charlie’s (Cannon in kit form) were the smallest servo

available and a feat in their day – but look at the response speed.

Table4

Accuracy

Like many digital display devices this one reads out to

unrealistic precision. The specs say accuracy is 1µS +/- 10%. “10% of what?”

is the issue. Times in µS are reasonable for measurement of signal pulse

width but not servo movement. There is no information on precisely how this

gadget works but I assume it just measures the time between start of

acceleration and end of deceleration. There is going to be some imprecision

about this no matter how good the timing circuits are. I would suggest a

basic accuracy of perhaps 1 mS for servo traverse is both reasonable and

entirely adequate, not the 10 µS that is displayed. I found variations over

10 cycles of less than 3 mS with a new Hitec servo on a 6V supply so I’m

assuming the S1 itself is probably good for at least 1 mS accuracy and

anything more is servo variation. In other words I think what the specs mean

is the READOUT is good to 1 microsecond not the accuracy. In any event this

is more than adequate. It’s pretty clear from the numbers above that the

variation between cycles and between individual servos of the same type is

significant. In general the better the quality of the servo the less

variation. Those old 70’s Charlies servos I built from a kit were a wonder

in their day but a HobbyKing $2.99 special leaves them for dead!

I did quite a number of tests on different servos using a

variety of power supplies and I came to the following conclusions:

This is a uniquely useful device. There are other servos

testers of varying complexity but all the ones I have seen are really just

servo drivers. I am unaware of any other low cost device that actually

measures the servo cycle speed. Be interested if anyone knows of another.

It is low cost and simple to use. Once you get the hang

of it you can test a bunch of servos in a few minutes. I found surprising

variation between “identical” servos and also between specified and actual

performance – particularly at the low-cost generic end of the spectrum.

I’m not into helis but I know there is a great need for

speed in the tail rotor servo in particular. This would seem to be a good

investment there. |